- Description

- Features

- Specifications

- Applications

- Ordering

- Documents

The RuggedNet GL/Mi is a managed industrial gigabit Ethernet switch that features copper or fiber uplink ports and four single-pair 10BASE-T1L Ethernet copper user ports.

The Single Pair Ethernet switch features four IEEE 802.3cg compliant 10BASE-T1L 3-pin SPE terminal ports or IEC 63171-2 SPE ports and two 10/100/1000 RJ-45 or 100/1000 fiber uplink ports.

The RuggedNet GL/Mi is a standard Layer 2 Ethernet switch that forwards frames to any port based on their MAC address.

The switch supports Dual Device mode, Directed Switch mode and Redundant Uplinks.

Dual Device mode that enables the module to operate as two independent and isolated Ethernet switches. In Dual Device mode, the GL/Mi provides separate and independent data traffic paths between the two uplink ports and four user ports.

Directed Switch mode directs multicast traffic (such as video) only to the appropriate uplink port, preventing the multicast video traffic from flooding other network ports.

Redundant fiber or copper uplinks provide protection and restoration for critical applications. In the event of a failure on the primary uplink port, the switch will failover to the secondary uplink port. Once the failed uplink port has been restored, the switch will return to the primary uplink port.

For daisy-chain applications, the second uplink port can be used to cascade multiple switches.

The mode of operation can be configured using easily accessible DIP-switches or using Web, Telnet, SSH, SNMPv1/v2c/v3 or Serial Console management interfaces. IPv4 and IPv6 are supported on the switches. These management interfaces provide access to filtering and security options, such as, broadcast storm prevention, IGMP, IEEE 802.1x, RADIUS, TACACS+ and Access Control Lists. Email notification and alarm reporting is provided.

The Small Form Pluggable (SFP) transceiver receptacle ports support 10/100/1000BASE-T and 1000BASE-T copper transceivers and 100Mbps and 1000Mbps standard, CWDM and DWDM fiber transceivers in a variety of distances and fiber types.

The switch can be wall or rack mounted using a wall mount bracket (8260-3) and shelf (8260-0) or DIN-rail mounted using the included DIN-rail mounting clip. The switch is available with dual DC input power.

2912-0-40-2Z, 2912-1-40-2Z, 2912-0-42-2Z, 2912-1-42-2Z

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Managed Industrial Single-Pair Ethernet switch

- Modbus Industrial Protocol for device management and monitoring

- Supports IPv4 and IPv6

- IEEE 802.1x, RADIUS, TACACS+ and ACL

- Email Notification

- Rapid and Multiple Spanning Tree Protocol

- Media Redundancy Protocol (MRP)

- IEEE 802.1ax LAG and LACP; Active/Active and Active/Standby

- IEEE 802.1Q VLAN tagging and IEEE 802.1ad Q-in-Q

- Broadcast / Multicast / Unicast Storm Prevention

- DHCP Relay Option 82, DHCPv6 and DHCPv6 Relay

- IPv4 IGMP and IPv6 MLD snooping

- Rate Limiting, Queue prioritization and Class of Service

- IEEE 802.1ab Link Layer Discovery Protocol

- Static MAC configuration and blocking of unknown Unicast/Multicast addresses

- Management via Web, Telnet, SSH, SNMPv1/v2c/v3 and serial interfaces

- Easy to use Hierarchical Command Line Interface

- SNMP management via Omnitron’s NetOutlook® management software, or third-party SNMP software

- Free 24/7/365 Technical Support

ADDITIONAL FEATURES

- Dual Device mode for operating as two separate switches

- Directed Switch mode prevents flooding of multicast traffic

- Four IEEE 802.3cg Single-Pair Ethernet user ports

- Supports 3-Pin SPE Terminal connector or IEC 63171-2 SPE connector

- Two SFP or two 10/100/1000 RJ-45 uplink ports

- Supports 10/100/1000 and 1G copper SFP transceivers

- Supports 100Mbps and 1000Mbps fiber SFPs

- Alarm contacts and sensors

- Dual DC power for redundancy

- Wall, Rack and DIN-rail mountable

- Fan-less design for long life

- Industrial (-40º to 75ºC) operating temperature

- TAA, BAA and NDAA compliant, and Made in the USA

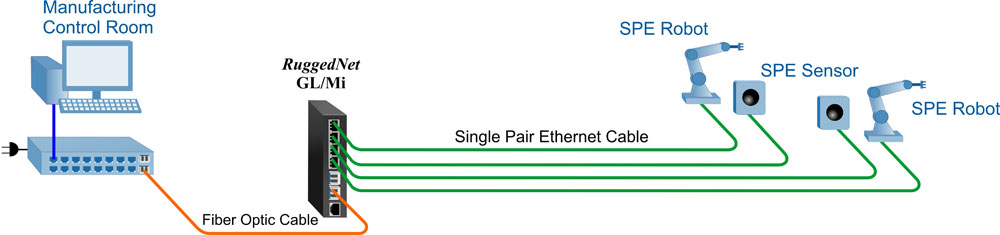

Industrial Manufacturing Application

This application example illustrates how industrial devices, that excess the standard 100 meter distance of Ethernet, can be connected to a remote Manufacturing Control Room using the SPE cabling. Each SPE device is connected to a RuggedNet GL/Mi Single Pair Ethernet switch using SPE cabling. The RuggedNet switch is connected to the Control Room using fiber optic cabling.

The RuggedNet switch, SPE robots and sensors will require an external power source.

Step 1: Choose a Base Part Number (2912-x-4c-2Z)

| Model Number | Description |

|---|---|

| 2912-0-4c-2Z | 4 x 10BASE-T1L + 2 x 100/1000 SFP Ports |

| 2912-1-4c-2Z | 4 x 10BASE-T1L + 2 x 10/100/1000 RJ-45 Ports |

Step 2: Choose a SPE Connector Type (2912-x-4c-2Z)

| 0 = 3-pin SPE Terminal Connector |

| 2 = IEC 63171-2 SPE Connector |

Power Option (2912-x-4c-2Z)

| 2 = Dual DC 2-Pin Terminal Power Connectors |

Operating Temperature Range (2912-x-4c-2Z)

| Z = Extended temperature (-40 to 75°C) |

| Accessories | ||

|---|---|---|

| Model Number | Description |  |

| 8260-3 | Wall Mounting Plate | |

| 8260-0 | 19" rack mount shelf | |

OmniConverter / RuggedNet SPE Web Interface (User Manual)

OmniConverter / RuggedNet SPE NOL (User Manual)

OmniConverter / RuggedNet SPE Hierarchical CLI (User Manual)

2912-0-40-2Z, 2912-1-40-2Z, 2912-0-42-2Z, 2912-1-42-2Z